Chesapeake Machining & Fabrication, Inc. stands at the forefront of innovation with its unwavering commitment to incorporating the latest machines and cutting-edge technologies in its operations. Renowned for its dedication to precision and efficiency, Chesapeake’s state-of-the-art facility boasts a remarkable array of the most advanced machining and fabrication equipment available today. This includes an impressive lineup of computer-numerical-control (CNC) machines that enable intricate designs and the highest degree of accuracy.

Lagun GBR4 and BS-4 Moving Table Machining Centers

Lagun GBR4 and BS-4 Moving Table Machining Centers

Butler Elgamill HE – 4000 Traveling Column

Butler Elgamill HE – 4000 Traveling Column

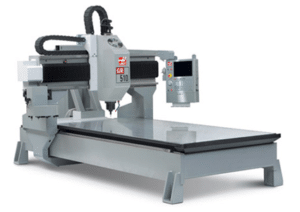

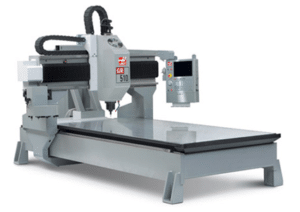

Haas GR512 Gantry Mill

Haas GR512 Gantry Mill

Haas (2) VF10 CNC Vertical Machining Center

Haas (2) VF10 CNC Vertical Machining Center

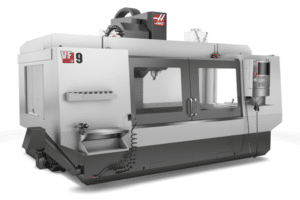

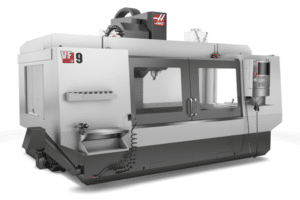

Haas VF9 CNC Vertical Machining Center

Haas VF9 CNC Vertical Machining Center

Haas VF-3 CNC Vertical Machining Center

Haas VF-3 CNC Vertical Machining Center

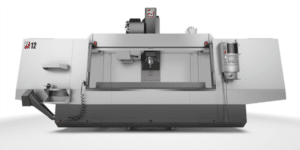

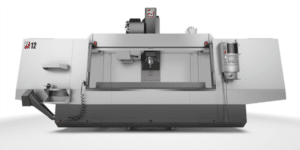

Haas VF-12 CNC Vertical Machining Center

Haas VF-12 CNC Vertical Machining Center

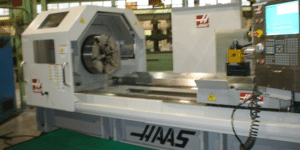

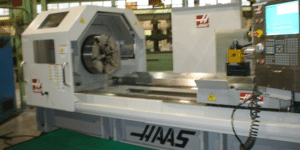

Haas TL-4 CNC Lathe

Haas TL-4 CNC Lathe

| Lebond Collet Lathe | 16″ swing | 3″ centers |

| Lebond Collet Lathe | 16″ swing | 4-1/2″ centers |

| Lebond Collet Lathe | 24″ swing | 12″ centers |

| Lebond Collet Lathe | 24″ swing | 4-1/2″ centers |

To support our ISO 9001 and AISC certified quality programs, Chesapeake Machining & Fabrication Inc. has a full complement to measuring tools and equipment capable of accurately measuring the equipment that we manufacture. All of our tools and equipment are calibrated with standards traceable to NIST and in addition to our manual measurement tools, we have the following portable CMM’s. If needed, we can tailor our program to meet your specific Quality Assurance requirements.

To insure that your part’s meet the most stringent requirements, our quality management system is compliant with ISO 9001 and certified by The American Institute of Steel Construction (AISC). for Building Fabrications, Bridge Fabrications – Simple, Highway Component Manufacturing , and Hydraulic Fabrications – Advanced. All welders at Chesapeake Machining & Fabrication, Inc. hold AWS D1.1 certification as a minimum with many welders having additional certifications to AWS D1.2 AWS D1.3, AWS D1.5, AWS D1.6 D14.1 and others. View or current AISC certification.

Lagun GBR4 and BS-4 Moving Table Machining Centers

Lagun GBR4 and BS-4 Moving Table Machining Centers

Butler Elgamill HE – 4000 Traveling Column

Butler Elgamill HE – 4000 Traveling Column

Haas GR512 Gantry Mill

Haas GR512 Gantry Mill

Haas (2) VF10 CNC Vertical Machining Center

Haas (2) VF10 CNC Vertical Machining Center

Haas VF9 CNC Vertical Machining Center

Haas VF9 CNC Vertical Machining Center

Haas VF-3 CNC Vertical Machining Center

Haas VF-3 CNC Vertical Machining Center

Haas VF-12 CNC Vertical Machining Center

Haas VF-12 CNC Vertical Machining Center

Haas TL-4 CNC Lathe

Haas TL-4 CNC Lathe

| Lebond Collet Lathe | 16″ swing | 3″ centers |

| Lebond Collet Lathe | 16″ swing | 4-1/2″ centers |

| Lebond Collet Lathe | 24″ swing | 12″ centers |

| Lebond Collet Lathe | 24″ swing | 4-1/2″ centers |

To support our ISO 9001 and AISC certified quality programs, Chesapeake Machining & Fabrication Inc. has a full complement to measuring tools and equipment capable of accurately measuring the equipment that we manufacture. All of our tools and equipment are calibrated with standards traceable to NIST and in addition to our manual measurement tools, we have the following portable CMM’s. If needed, we can tailor our program to meet your specific Quality Assurance requirements.

To insure that your part’s meet the most stringent requirements, our quality management system is compliant with ISO 9001 and certified by The American Institute of Steel Construction (AISC). for Building Fabrications, Bridge Fabrications – Simple, Highway Component Manufacturing , and Hydraulic Fabrications – Advanced. All welders at Chesapeake Machining & Fabrication, Inc. hold AWS D1.1 certification as a minimum with many welders having additional certifications to AWS D1.2 AWS D1.3, AWS D1.5, AWS D1.6 D14.1 and others. View or current AISC certification.

Machining

Fabrication

Join our email list for periodic updates on Chesapeake Machining and Fabrication’s services.